Methane is a robust greenhouse gasoline, and inside the pig meat provide chain, methane accounts for round 25% of greenhouse gasoline emissions. The lifetime of methane within the ambiance is brief in comparison with that of CO2, and subsequently methane mitigation on farms may make an essential contribution to curb world warming within the quick time period.

On pig farms, manure storage is answerable for 85% of methane emissions, and subsequently manure administration is the principle goal for mitigation. Amongst a number of methods for dealing with or therapy at present investigated, low-dose acidification of liquid manure is a novel method that could possibly be a versatile and cost-effective know-how for local weather motion.

Methane formation and mechanism of inhibition

Methane is produced by specialised microorganisms (methanogens) that work together with a number of different teams of microorganisms to degrade the natural matter in manure. The methanogens which can be energetic in slurry are completely different from these within the digestive system of the animals, and slurry acidification works by delaying the variation and progress of the “new” methanogens who will be energetic on this irritating atmosphere.

Slurry acidification with sulfuric acid will change chemical balances that inhibit methanogens. Moreover, a specialised group of micro organism can make the most of sulfate from sulfuric acid, straight competing with methanogens and producing hydrogen sulfide, which additional reinforces methanogen inhibition. This may occasionally assist keep the inhibition over time.

What’s slurry acidification?

Acidification of slurry by concentrated sulfuric acid (96%) was developed round 25 years in the past in Denmark as a way to keep away from ammonia losses from slurry. Later it was found that this therapy additionally successfully lowered methane emissions, and that in truth a number of different compounds that include sulfur additionally present some inhibition (Petersen, et al. 2012).

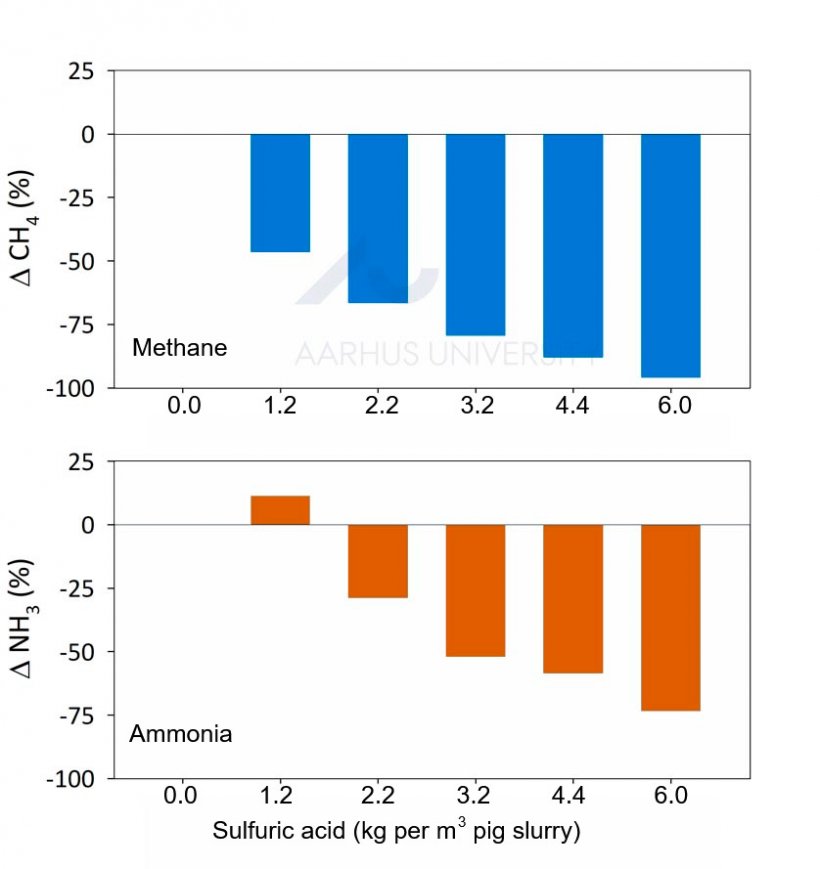

Research in a number of international locations have later confirmed these observations, and that sulfuric acid is essentially the most highly effective agent for inhibiting methane emissions. This led us to think about what can be the consequences of decreasing the sulfuric acid dose on methane and ammonia emissions. What’s the local weather profit with a decrease acid dose, and what are the tradeoffs by way of nitrogen losses and value financial savings?

A pilot-scale examine was carried out in 2021. It confirmed that low-dose acidification with 2 kg sulfuric acid per ton of pig slurry (one third of the prescribed dose for ammonia mitigation) could possibly be extremely cost-effective for methane mitigation however with much less discount of ammonia emissions (Ma, C., et al., 2022).

Determine 1. Danish rules prescribe the addition of 6 kg sulfuric acid per m3 pig slurry to scale back ammonia emissions. In a pilot examine, six completely different doses of acid (0 to six kg per m3) had been used. The 2 graphs present proportion modifications in methane and ammonia emissions, with untreated pig slurry as reference. Supply: Ma et al., 2022.

Slurry acidification on sensible farms

Concentrated sulfuric acid is hazardous, and technical options are wanted to make sure the well being and security of each workers and animals. A totally automated business know-how for slurry acidification in pig barns already exists, however funding prices are excessive. Slurry can be acidified in outdoors storage tanks, the place acid is added throughout vigorous mixing. This have to be completed by educated personnel utilizing the required security gear and procedures, and it’s usually carried out by a contractor.

Acidification in outdoors storage tanks is finished in the present day on many farms in Denmark, however shortly earlier than area utility. Right here, the aim is to scale back ammonia losses throughout spreading. Nonetheless, to scale back methane emissions throughout storage it’s essential to acidify the slurry in storage tanks in the course of the storage interval.

Methane emissions are significantly excessive throughout summer time and early autumn, and subsequently acidification ought to happen in June, and once more round 1 September. Recent slurry from barns will probably be pumped to the storage tank at common intervals. Sufficient acid must be added in June and September to permit for this dilution and nonetheless have a last focus of two kg sulfuric acid per m3 slurry on the finish of the storage interval.

Frequent slurry switch from the barn to a storage tank can improve the general discount of methane emissions from slurry by permitting acidification or different therapy applied sciences outdoors the barn. Nonetheless, many present pig barns have deep pits or shallow pits with a pull-plug system, which can’t be emptied regularly. There’s a have to develop and undertake new housing designs for improved manure administration.

Low-dose acidification to scale back methane emissions from storage services ought to happen in late spring. It’s at present achieved by including sulfuric acid (96%) throughout intense mixing. Photograph: Søs Lindeborg Pedersen, SEGES Innovation.

Verifying the efficacy of low-dose acidification

Primarily based on the promising outcomes at laboratory- and pilot-scale, the low-dose acidification know-how is now being evaluated at sensible scale in a examine that includes 16 slurry tanks, eight tanks on pig farms and one other eight on cattle farms. Six of the eight tanks are acidified. Slurry samples have been collected a number of occasions throughout storage in numerous positions and at a number of depths for evaluation of slurry composition and methane manufacturing charges.

There’s a have to have some slurry within the tank already when sulfuric acid is added, and subsequently pig slurry was acidified round 1 July and once more in September. Most tanks obtained contemporary slurry from the barn at common intervals.

The outcomes from the primary yr of the examine confirmed that methane manufacturing will be successfully inhibited. Nonetheless, in tanks with pig slurry, that are all backside fed, we have now typically seen pockets of slurry close to the inlet with excessive methane manufacturing charges even when the slurry was initially acidified. Due to this fact, additional work is required to optimize the therapy know-how and doc total methane mitigation. On-farm measurement campaigns will happen within the subsequent part of the undertaking.

In a brand new improvement, a system for addition of acid in the course of the pumping of slurry from barn to outdoors storage has been developed by a Danish firm and will probably be evaluated in 2025 on a pig farm and a cattle farm. This is able to decrease the necessity for on-farm dealing with of the acid whereas making certain rapid inhibition of methanogens.

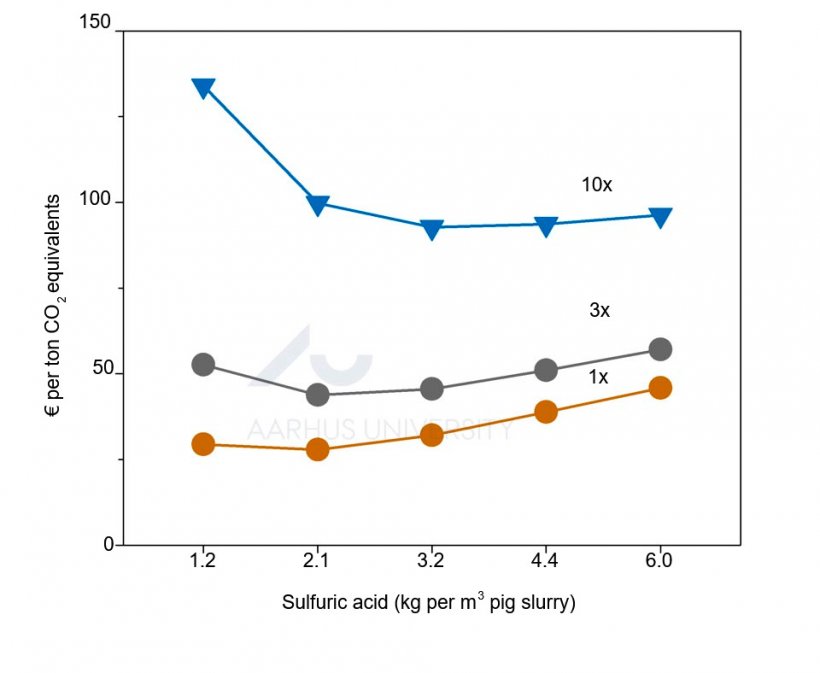

The price-effectiveness of low-dose acidification methods will probably be decided in spring 2026. A preliminary analysis of cost-effectiveness was completed primarily based on the outcomes from the pilot examine. The price of GHG mitigation, expressed as euros per ton of CO2 equivalents, had been calculated as a operate of acid dose and utility technique (1, 3, or 10 acid remedies) (Fig. 2). Prices thought-about had been acidification by a contractor, the worth of N financial savings from averted ammonia losses, methane mitigation, and the prevention of nitrous oxide emissions derived from ammonia.

Determine 2. Outcomes from the pilot-scale examine had been used to evaluate the economic system of slurry acidification for greenhouse gasoline mitigation. Value of GHG mitigation by acidification 1, 3, or 10 occasions yearly throughout storage of pig slurry. Supply: Ma et al., 2022.

The price of EU Carbon Permits is at present at 75€ per ton CO2 equivalents. Relying on the necessity for mixing throughout storage, low-dose acidification could possibly be an economical answer.

Acidifying pig slurry in storage tanks one to a few occasions per yr could possibly be an economical technique for mitigating greenhouse gasoline emissions in agriculture. Value effectivity will be additional enhanced by regularly transferring slurry from barns to out of doors storage tanks, permitting acidification to affect a bigger share of the full methane emissions from manure administration. Moreover, because the majority of CH₄ emissions happen throughout summer time and early autumn, making use of the complete acid dose—e.g., 2.1 kg of sulfuric acid/ m3 pig slurry within the last quantity—earlier than summer time may maximize mitigation in the course of the peak emission interval whereas stopping extreme sulfur enter into soils when the slurry is utilized within the area.