France’s European-level dedication to cut back ammonia emissions by 15% by 2030 in comparison with 2005 forces pig business gamers to think about new programs of motion, each in current amenities and in new development tasks. Temperature is without doubt one of the major elements that influences ammonia volatilization, together with pH. Whereas slurry acidification has not been remarkably profitable within the nation as a consequence of numerous technical, financial, and even social constraints, appearing on temperature is rising as an avenue of curiosity.

Throughout the framework of a challenge financed by ADEME and PNDAR, IFIP has coordinated a research targeted on two axes of temperature administration in ending barns: ambient temperature and slurry temperature.

Lowering the temperature of saved slurry: pit-bottom slurry cooling system vs. floating system

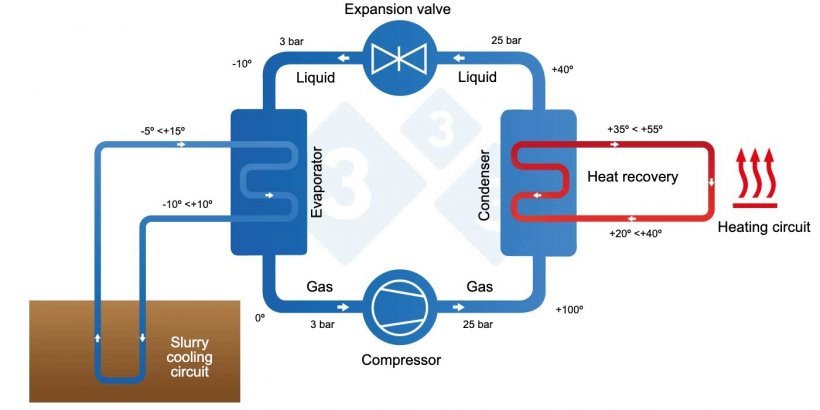

A part of the challenge has been devoted to implementing methods geared toward lowering the temperature of the slurry saved within the under-slat pits of ending pig barns. These slurry cooling methods include a community of pipes in touch with the saved slurry, that are linked to a warmth pump and a calorie assortment system. A warmth switch fluid circulates by this community, permitting the warmth to be captured from the slurry and transferred to a storage and/or consumption system. The warmth recovered from the slurry can be utilized, for instance, to warmth a sizzling water tank or to preheat the air in post-weaning or farrowing barns.

Schematic diagram of the workings of a slurry cooling system. Supply: IFIP.

Two slurry cooling methods had been put in in ending rooms at IFIP’s experimental station situated in Romillé, France:

- The primary system, “pit-bottom slurry cooling,” had a community of tubes fastened to the underside of the under-slat pit.

- The second, “floating slurry cooling”, had a pipe community connected to a floating platform on the slurry floor.

In each methods, the cooling capability was 20 W/m2.

Pit-bottom slurry cooling system below experimental circumstances. Supply: IFIP.

Floating slurry cooling system below experimental circumstances. Supply: IFIP.

4 batches of ending pigs had been monitored, each for animal efficiency (common every day achieve, feed conversion fee, carcass composition) and for environmental efficiency (ammonia, nitrous oxide and methane emissions, quantity and composition of slurry produced). Temperature sensors had been put in at numerous depths of the under-slat pit to measure the impact the kind of cooling system had on the slurry temperature.

Parallel to monitoring the batches of pigs within the IFIP experimental station, measurements had been additionally taken on a business farm geared up with a slurry cooling system on the backside of the pit, with an put in cooling energy of 10 W/m2. The monitoring protocol on this trial, carried out below business circumstances, was virtually similar to that adopted below experimental circumstances.

Methane discount with out affecting manufacturing yields

In experimental and on-farm circumstances, no variations in ending pig efficiency had been noticed between the totally different slurry cooling methods and the management rooms.

Within the IFIP research, pit-bottom slurry cooling decreased the slurry temperature by 10°C below experimental circumstances (solely 2.5°C below actual farm circumstances), whereas floor cooling solely achieved a 7°C discount.

| Emission (kg N/C per area and yr) | Experimental circumstances | Farm circumstances | |||

|---|---|---|---|---|---|

| Management room | Room with pit-bottom slurry cooling | Room with floor slurry cooling | Management room | Room with pit-bottom slurry cooling | |

| Ammonia | 2.2 ± 1.3 | 1.9 ± 1.4 | 2.3 ± 1.3 | 1.9 ± 0.9 | |

| Nitrous oxide | 0.08 ± 0.08 | 0.08 ± 0.08 | 0.09 ± 0.08 | nm | nm |

| Methane | 4.3 ± 2.9 | 1.8 ± 0.9 | 2.7 ± 1.2 | 13.0 ± 5.8 | 10.5 ± 5.1 |

nm : not measured

The gasoline emissions from the management rooms had been thought-about consultant after comparability with current literature. In rooms geared up with slurry cooling methods, ammonia emissions had been decreased by solely 14% below experimental circumstances, whereas no impact was measured below farm circumstances. Within the case of methane, the temperature discount slowed the exercise of methanogenic micro organism, leading to a 59% discount with pit-bottom cooling and a 38% discount with floor cooling, each below experimental circumstances. Beneath farm circumstances, this discount was solely 19%.

The progressive nature of this research lies in its methane outcomes, which different groups had not beforehand revealed. Slurry cooling is proven to be an efficient device for lowering methane emissions, whereas its effectiveness on ammonia has been decrease than that indicated within the literature. This distinction is defined by the put in cooling capability: the discount of ammonia is proportional to this capability (10% per 10 W/m² put in). This ratio explains the decrease effectivity noticed in farm circumstances (10 W/m² versus 20 W/m² within the experimental station).

Slurry cooling methods: An answer with potential and technical limits

Lowering the temperature of slurry is a promising method to restrict ammonia manufacturing on pig farms. Furthermore, this method gives a further benefit associated to vitality restoration, representing a major incentive for its improvement, particularly within the context of accelerating vitality prices. Nonetheless, adapting this method to current barns presents sure technical limitations, comparable to lowering the out there quantity within the under-slat pits.

Nadine Guingand, environmental engineer on the IFIP-Institut du porc.